Battery energy storage systems (ESS) place extremely stringent demands on battery cells, differing significantly from the focus on cells used in consumer electronics (such as mobile phones and laptops) or electric vehicles (EVs). Leading li ion battery manufacturers must adapt their designs specifically for these distinct needs.

Simply put, the core requirements for ESS battery cells are: ultra-high safety, ultra-long life, low cost, and high consistency, while requirements for energy density and rate performance are relatively relaxed. This is a primary focus for li ion battery manufacturers targeting the ESS market.

Simply put, the core requirements for ESS battery cells are: ultra-high safety, ultra-long life, low cost, and high consistency, while requirements for energy density and rate performance are relatively relaxed. This is a primary focus for li ion battery manufacturers targeting the ESS market.

Below, I will elaborate on these requirements from several key perspectives:

1. Core Requirements

a. Safety Performance - The Most Important and Core Requirement

Energy storage systems are typically installed in centralized locations, possess enormous capacities (on the order of megawatt-hours), and are often located near people or equipment. If thermal runaway occurs, the consequences can be disastrous. Therefore, safety is an absolute priority for li ion battery manufacturers.

•Thermal Stability: The battery cell material system (positive electrode, negative electrode, and electrolyte) must have a high thermal runaway onset temperature, meaning it must be highly resistant to high temperatures and not prone to decomposition, combustion, or explosion under abusive conditions (such as overcharging, short circuiting, and extrusion).

•Mechanical Safety: The battery cell structure must be robust and able to withstand rigorous tests such as needle penetration, extrusion, and heavy object impact. Currently, lithium iron phosphate (LFP) batteries are the undisputed mainstream choice for ESS due to their superior thermal stability, far surpassing ternary lithium (NMC) batteries.

•System-Level Protection: The battery cell design from li ion battery manufacturers must facilitate system-level safety features, such as thermal management, pressure relief valve design, and the inclusion of flame-retardant and thermal insulation materials.

b. Cycle Life and Calendar Life - Key Determinants of Economic Viability

Energy storage projects have a long payback period (typically 8-15 years), requiring battery cells to be extremely durable.

•Cycle Life: Typically, a requirement is >6,000 cycles (capacity retained at or above 80% at 80% depth of discharge). Top-tier products from advanced li ion battery manufacturers can achieve 12,000 cycles or even higher. This means daily charging and discharging can provide over 16 years of use.

•Calendar Life: Even without use, batteries naturally age. ESS cells require a calendar life of 15-20 years. This places extremely high demands on the cell's chemistry, sealing, and reliability, which is a key challenge for li ion battery manufacturers.

c. Cost - The Engine Driving Large-Scale Adoption

While ensuring safety and longevity, cost per watt-hour is the core consideration.

•Material Cost: LFP batteries, because they do not contain expensive metals such as cobalt and nickel, have lower raw material costs.

•Production Efficiency: Li ion battery manufacturers target large-scale, standardized production to reduce manufacturing costs. Large battery cells (e.g., 280Ah and above) have become mainstream because they reduce the number of connectors in system integration, lowering costs and points of failure.

d. Consistency and Reliability - The Cornerstone of Stable System Operation

A single energy storage container consists of thousands of battery cells connected in series and parallel, making cell consistency crucial.

•Initial Consistency: The initial deviation in parameters such as capacity, voltage, and internal resistance within a batch of cells must be minimal.

•Degradation Consistency: The rate and degree of degradation of all cells must be consistent during long-term charging, discharging, and storage. Inconsistency can lead to a "barrel effect" in the system, rapidly reducing overall available capacity and even causing safety issues. This requires exceptional process control from li ion battery manufacturers.

•Production Process: This places extreme demands on battery cell manufacturers' process control and quality management systems.

e. Energy Density and Power Density - Relatively Less Important Requirements

•Energy Density: ESS is less sensitive to size and weight than consumer electronics and electric vehicles, so energy density is a relatively less important metric. While LFP batteries have a lower energy density than NMC batteries, they fully meet the requirements of stationary energy storage.

•Power Density: Different application scenarios have different requirements. For scenarios requiring rapid response, such as grid frequency regulation, higher rate performance (such as 2C charge/discharge) is required. For peak shaving and valley filling (1-2 cycles per day), efficiency and lifespan at lower rates (0.25C-0.5C) are more important.

f. Efficiency and Self-Discharge Rate - Impacting Daily Profit

•Energy Efficiency: The higher the round-trip efficiency of charge and discharge, the better (typically >95%). High energy efficiency means less energy is wasted during storage, directly increasing project profitability.

•Self-Discharge Rate: The self-discharge rate should be as low as possible. A high self-discharge rate means faster degradation of the battery cells during storage and exacerbates system inconsistencies.

Energy storage systems are typically installed in centralized locations, possess enormous capacities (on the order of megawatt-hours), and are often located near people or equipment. If thermal runaway occurs, the consequences can be disastrous. Therefore, safety is an absolute priority for li ion battery manufacturers.

•Thermal Stability: The battery cell material system (positive electrode, negative electrode, and electrolyte) must have a high thermal runaway onset temperature, meaning it must be highly resistant to high temperatures and not prone to decomposition, combustion, or explosion under abusive conditions (such as overcharging, short circuiting, and extrusion).

•Mechanical Safety: The battery cell structure must be robust and able to withstand rigorous tests such as needle penetration, extrusion, and heavy object impact. Currently, lithium iron phosphate (LFP) batteries are the undisputed mainstream choice for ESS due to their superior thermal stability, far surpassing ternary lithium (NMC) batteries.

•System-Level Protection: The battery cell design from li ion battery manufacturers must facilitate system-level safety features, such as thermal management, pressure relief valve design, and the inclusion of flame-retardant and thermal insulation materials.

b. Cycle Life and Calendar Life - Key Determinants of Economic Viability

Energy storage projects have a long payback period (typically 8-15 years), requiring battery cells to be extremely durable.

•Cycle Life: Typically, a requirement is >6,000 cycles (capacity retained at or above 80% at 80% depth of discharge). Top-tier products from advanced li ion battery manufacturers can achieve 12,000 cycles or even higher. This means daily charging and discharging can provide over 16 years of use.

•Calendar Life: Even without use, batteries naturally age. ESS cells require a calendar life of 15-20 years. This places extremely high demands on the cell's chemistry, sealing, and reliability, which is a key challenge for li ion battery manufacturers.

c. Cost - The Engine Driving Large-Scale Adoption

While ensuring safety and longevity, cost per watt-hour is the core consideration.

•Material Cost: LFP batteries, because they do not contain expensive metals such as cobalt and nickel, have lower raw material costs.

•Production Efficiency: Li ion battery manufacturers target large-scale, standardized production to reduce manufacturing costs. Large battery cells (e.g., 280Ah and above) have become mainstream because they reduce the number of connectors in system integration, lowering costs and points of failure.

d. Consistency and Reliability - The Cornerstone of Stable System Operation

A single energy storage container consists of thousands of battery cells connected in series and parallel, making cell consistency crucial.

•Initial Consistency: The initial deviation in parameters such as capacity, voltage, and internal resistance within a batch of cells must be minimal.

•Degradation Consistency: The rate and degree of degradation of all cells must be consistent during long-term charging, discharging, and storage. Inconsistency can lead to a "barrel effect" in the system, rapidly reducing overall available capacity and even causing safety issues. This requires exceptional process control from li ion battery manufacturers.

•Production Process: This places extreme demands on battery cell manufacturers' process control and quality management systems.

e. Energy Density and Power Density - Relatively Less Important Requirements

•Energy Density: ESS is less sensitive to size and weight than consumer electronics and electric vehicles, so energy density is a relatively less important metric. While LFP batteries have a lower energy density than NMC batteries, they fully meet the requirements of stationary energy storage.

•Power Density: Different application scenarios have different requirements. For scenarios requiring rapid response, such as grid frequency regulation, higher rate performance (such as 2C charge/discharge) is required. For peak shaving and valley filling (1-2 cycles per day), efficiency and lifespan at lower rates (0.25C-0.5C) are more important.

f. Efficiency and Self-Discharge Rate - Impacting Daily Profit

•Energy Efficiency: The higher the round-trip efficiency of charge and discharge, the better (typically >95%). High energy efficiency means less energy is wasted during storage, directly increasing project profitability.

•Self-Discharge Rate: The self-discharge rate should be as low as possible. A high self-discharge rate means faster degradation of the battery cells during storage and exacerbates system inconsistencies.

2. Mainstream Technology Route: Why Lithium Iron Phosphate (LFP)?

Currently, over 95% of new electrochemical energy storage projects worldwide use lithium iron phosphate (LiFePO₄, LFP) cells. This is because they perfectly meet the core requirements of the aforementioned ESS, making them the preferred choice for most li ion battery manufacturers in this sector.

a. Extreme Safety: Their strong phosphorus-oxygen bond and extremely high thermal stability make them resistant to decomposition at high temperatures, and their thermal runaway onset temperature is much higher than that of ternary lithium batteries.

b. Ultra-Long Life: Their stable crystal structure and minimal volume change during cycling result in an extremely long cycle life.

c. Low Cost: They contain no precious metals such as cobalt and nickel, and their raw materials are widely available and relatively stable in price.

d. Excellent Consistency: The technology is mature, and the production process is easy to control.

In contrast, ternary lithium ion (NMC) batteries, while offering high energy density, struggle to meet the stringent safety and lifespan requirements of ESS, leading to a significant decline in their use in the energy storage sector.

a. Extreme Safety: Their strong phosphorus-oxygen bond and extremely high thermal stability make them resistant to decomposition at high temperatures, and their thermal runaway onset temperature is much higher than that of ternary lithium batteries.

b. Ultra-Long Life: Their stable crystal structure and minimal volume change during cycling result in an extremely long cycle life.

c. Low Cost: They contain no precious metals such as cobalt and nickel, and their raw materials are widely available and relatively stable in price.

d. Excellent Consistency: The technology is mature, and the production process is easy to control.

In contrast, ternary lithium ion (NMC) batteries, while offering high energy density, struggle to meet the stringent safety and lifespan requirements of ESS, leading to a significant decline in their use in the energy storage sector.

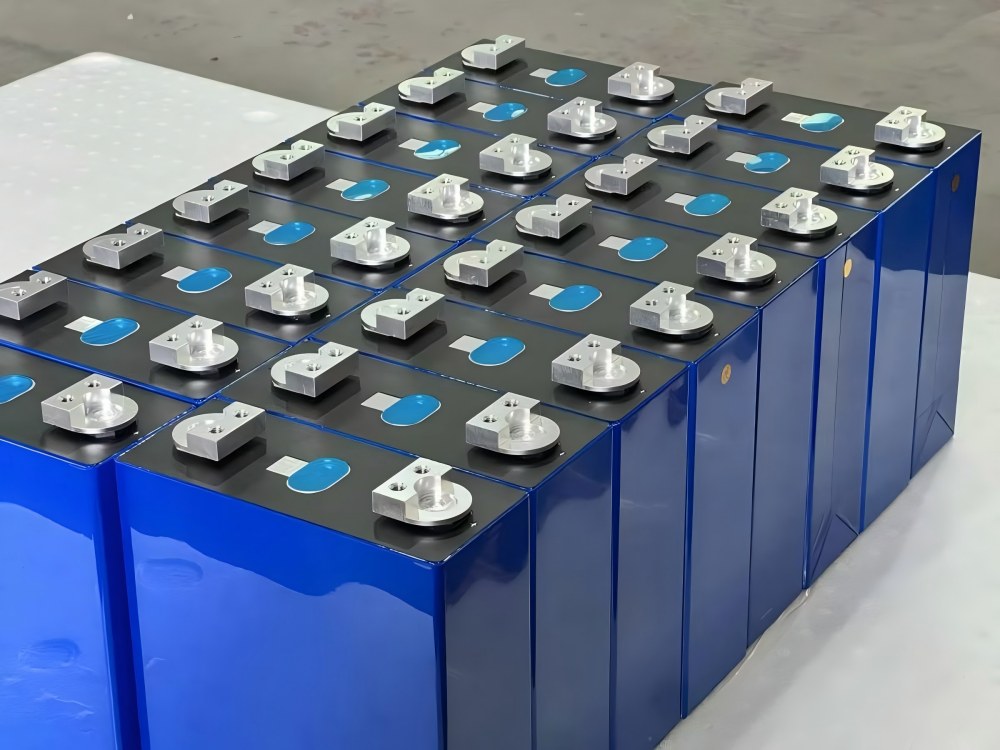

3. Cell Form Factor: Prismatic Aluminum Cases Are the Mainstream

Prismatic aluminum case batteries are the dominant form factor in the current ESS market. They offer high structural strength, high assembly efficiency, ease of heat dissipation design, and long lifespan, making them ideal for large-scale energy storage systems. Most li ion battery manufacturers specializing in ESS produce this form factor.

Cylindrical batteries, such as large cylindrical batteries like the 4680, offer the advantages of standardization and high production efficiency, but their integration can be less compact and present thermal management challenges in ESS systems. They are used in some industrial and commercial energy storage applications.

Pouch cells offer high energy density but poorer mechanical strength. Assembly requires additional support structures and demands high long-term reliability for edge sealing, making them less commonly used in large-scale ESS systems.

Cylindrical batteries, such as large cylindrical batteries like the 4680, offer the advantages of standardization and high production efficiency, but their integration can be less compact and present thermal management challenges in ESS systems. They are used in some industrial and commercial energy storage applications.

Pouch cells offer high energy density but poorer mechanical strength. Assembly requires additional support structures and demands high long-term reliability for edge sealing, making them less commonly used in large-scale ESS systems.

Summary

Battery cells in battery energy storage systems can be summarized as follows:

•Safety is the "1," and all other characteristics are the "0s" behind it. Without safety, everything is zero.

•Lifespan is the "core," directly determining whether the economic model of an energy storage project is viable.

•Cost is the "driving force," and low cost is key to promoting large-scale adoption.

•Consistency is the "guarantee," ensuring long-term stable and reliable operation of systems composed of thousands of cells.

•Technical path is the "consensus," and lithium iron phosphate (LFP) prismatic batteries are the technology of choice that best meets all of these requirements, both currently and for the foreseeable future, a trend clearly recognized by all major li ion battery manufacturers.

•Safety is the "1," and all other characteristics are the "0s" behind it. Without safety, everything is zero.

•Lifespan is the "core," directly determining whether the economic model of an energy storage project is viable.

•Cost is the "driving force," and low cost is key to promoting large-scale adoption.

•Consistency is the "guarantee," ensuring long-term stable and reliable operation of systems composed of thousands of cells.

•Technical path is the "consensus," and lithium iron phosphate (LFP) prismatic batteries are the technology of choice that best meets all of these requirements, both currently and for the foreseeable future, a trend clearly recognized by all major li ion battery manufacturers.

Contact our team today for a complimentary, customized consultation!

Inquiry more product details from the : Lithium Ion Battery Manufacturers

WhatsApp/Wechat/Mobile: +86 13332949210

Email: info@xihobattery.com

Website: www.xihopower.com

WhatsApp/Wechat/Mobile: +86 13332949210

Email: info@xihobattery.com

Website: www.xihopower.com

+86 13332949210

+86 13332949210 info@xihobattery.com

info@xihobattery.com

Xiho

Xiho Oct 30 2025

Oct 30 2025