Explore the core advantages of battery composite current collectors and their innovation in lithium-ion battery (LiB) performance.

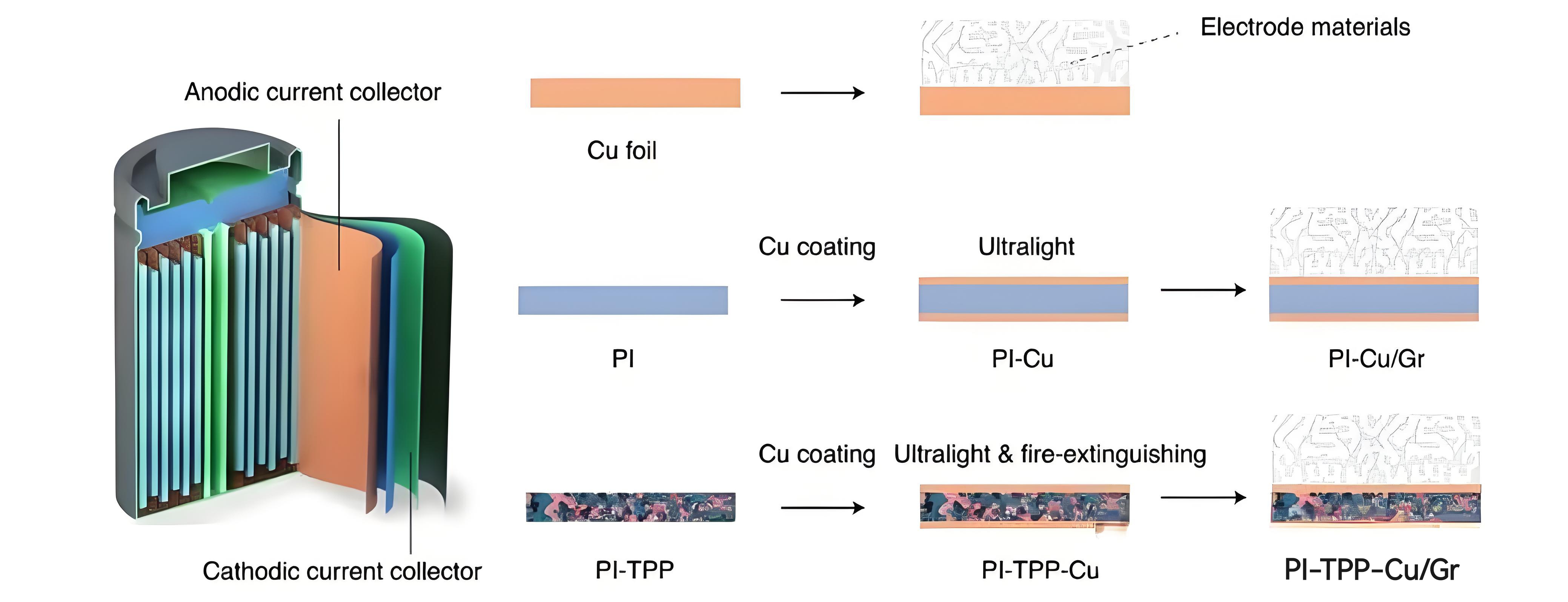

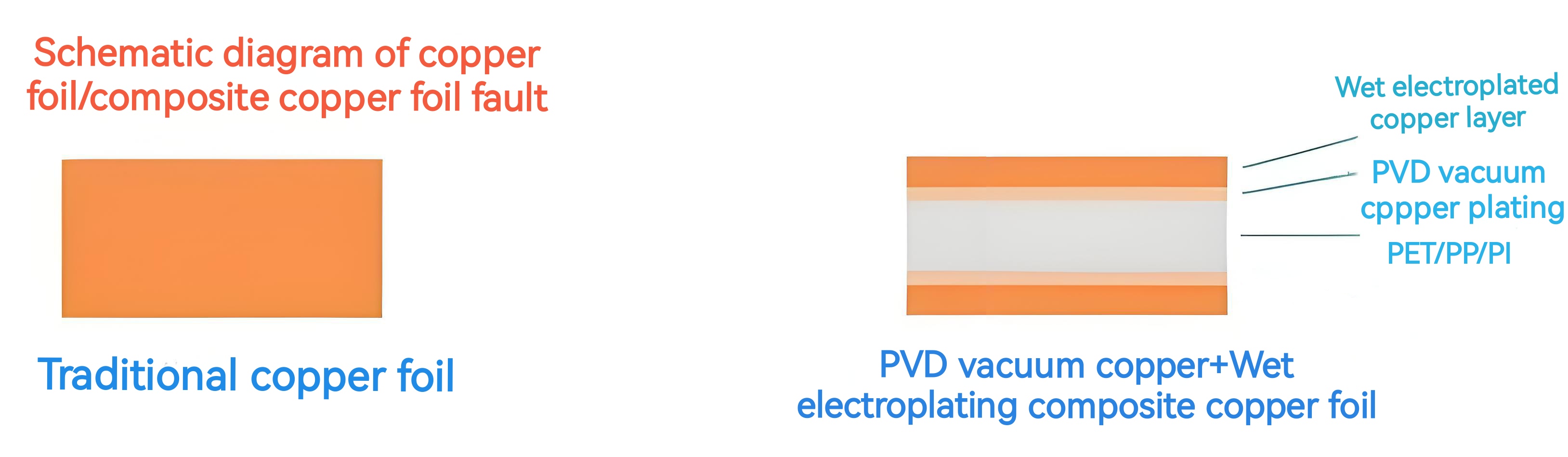

In recent years, with the rapid development of electric vehicles and energy storage systems, the performance optimization and safety requirements of lithium batteries have become increasingly urgent. In this context, battery composite current collectors have become the focus of the industry with their "sandwich" structure (polymer substrate + metal coating). This article will analyze its core advantages and compare it with traditional current collectors to explore its far-reaching impact on lithium battery storage and rechargeable lithium battery.

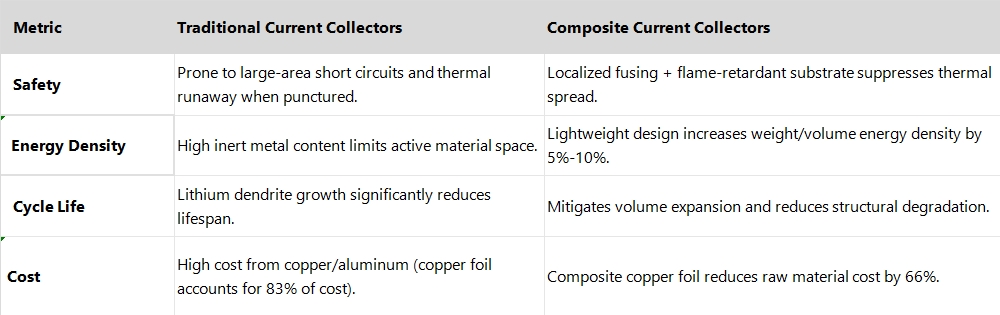

1. Four core advantages of composite current collectors

(1) High safety: End the risk of thermal runaway

Fuse effect: The thin metal layer of the composite current collector melts when short-circuited, forming a "point break", effectively inhibiting the spread of heat.

Flame-retardant substrate: Polymer materials such as PET and PP are resistant to high temperatures and non-flammable, significantly reducing the probability of lithium battery fire.

Inhibition of lithium dendrites: Reduce the risk of lithium metal penetrating the diaphragm and avoid lithium battery safety accidents caused by internal short circuits.

(2) High energy density: Lightweight design breaks bottlenecks

The density of the polymer substrate is only 1/6~1/8 of that of copper. The composite current collector can reduce the weight by 50%-80%, directly increasing the weight energy density of the rechargeable lithium battery by 5%-10%. At the same time, thinning the metal layer frees up space to accommodate more active substances.

(3) Long cycle life: delaying capacity attenuation

The polymer layer buffers electrode expansion stress and reduces structural damage; uniform current distribution delays polarization and extends the life of the lithium battery storage system.

(4) Low cost: dual optimization of materials and processes

The raw material cost of composite copper foil is only 34% of that of traditional copper foil, and the vacuum coating process reduces pollution, promoting large-scale application.

Fuse effect: The thin metal layer of the composite current collector melts when short-circuited, forming a "point break", effectively inhibiting the spread of heat.

Flame-retardant substrate: Polymer materials such as PET and PP are resistant to high temperatures and non-flammable, significantly reducing the probability of lithium battery fire.

Inhibition of lithium dendrites: Reduce the risk of lithium metal penetrating the diaphragm and avoid lithium battery safety accidents caused by internal short circuits.

(2) High energy density: Lightweight design breaks bottlenecks

The density of the polymer substrate is only 1/6~1/8 of that of copper. The composite current collector can reduce the weight by 50%-80%, directly increasing the weight energy density of the rechargeable lithium battery by 5%-10%. At the same time, thinning the metal layer frees up space to accommodate more active substances.

(3) Long cycle life: delaying capacity attenuation

The polymer layer buffers electrode expansion stress and reduces structural damage; uniform current distribution delays polarization and extends the life of the lithium battery storage system.

(4) Low cost: dual optimization of materials and processes

The raw material cost of composite copper foil is only 34% of that of traditional copper foil, and the vacuum coating process reduces pollution, promoting large-scale application.

2. Key comparison with traditional current collectors

3. Transformative impact on power batteries and energy storage systems

(1) Power battery: dual upgrade of battery life and safety

High energy density: Extends the range of electric vehicles and supports fast charging (such as composite copper foil to reduce the risk of lithium plating).

Thermal runaway protection: Meets automotive-grade safety standards and reduces the risk of collision/puncture conditions.

(2) Energy storage system: a win-win situation of economy and reliability

Long life: adapt to the frequent charging and discharging needs of grid energy storage and reduce maintenance costs.

Cost advantage of lithium battery storage: material and process optimization reduces initial investment, and the corrosion resistance of PP substrate extends the life in harsh environments.

High energy density: Extends the range of electric vehicles and supports fast charging (such as composite copper foil to reduce the risk of lithium plating).

Thermal runaway protection: Meets automotive-grade safety standards and reduces the risk of collision/puncture conditions.

(2) Energy storage system: a win-win situation of economy and reliability

Long life: adapt to the frequent charging and discharging needs of grid energy storage and reduce maintenance costs.

Cost advantage of lithium battery storage: material and process optimization reduces initial investment, and the corrosion resistance of PP substrate extends the life in harsh environments.

4. Challenges and future directions

Despite the promising prospects, composite current collectors still need breakthroughs:

Conductivity optimization: magnetron sputtering + water electroplating three-step method to improve the uniformity of the metal layer.

Interface bonding: Introduce an aluminum oxide intermediate layer to enhance adhesion.

Corrosion resistance: Develop PP substrate alternatives or Al-W alloy coatings.

Battery composite current collectors are reshaping the lithium battery industry through lightweight, high safety and low-cost design. Whether it is the high performance requirements of power batteries or the economic goals of lithium battery storage, this technology will become a key driver of future energy transformation. With the maturity of technology and innovative breakthroughs, composite current collectors are expected to fully enable the next generation of rechargeable lithium battery applications!

Conductivity optimization: magnetron sputtering + water electroplating three-step method to improve the uniformity of the metal layer.

Interface bonding: Introduce an aluminum oxide intermediate layer to enhance adhesion.

Corrosion resistance: Develop PP substrate alternatives or Al-W alloy coatings.

Battery composite current collectors are reshaping the lithium battery industry through lightweight, high safety and low-cost design. Whether it is the high performance requirements of power batteries or the economic goals of lithium battery storage, this technology will become a key driver of future energy transformation. With the maturity of technology and innovative breakthroughs, composite current collectors are expected to fully enable the next generation of rechargeable lithium battery applications!

+86 13332949210

+86 13332949210 info@xihobattery.com

info@xihobattery.com

Xiho

Xiho May 23 2025

May 23 2025