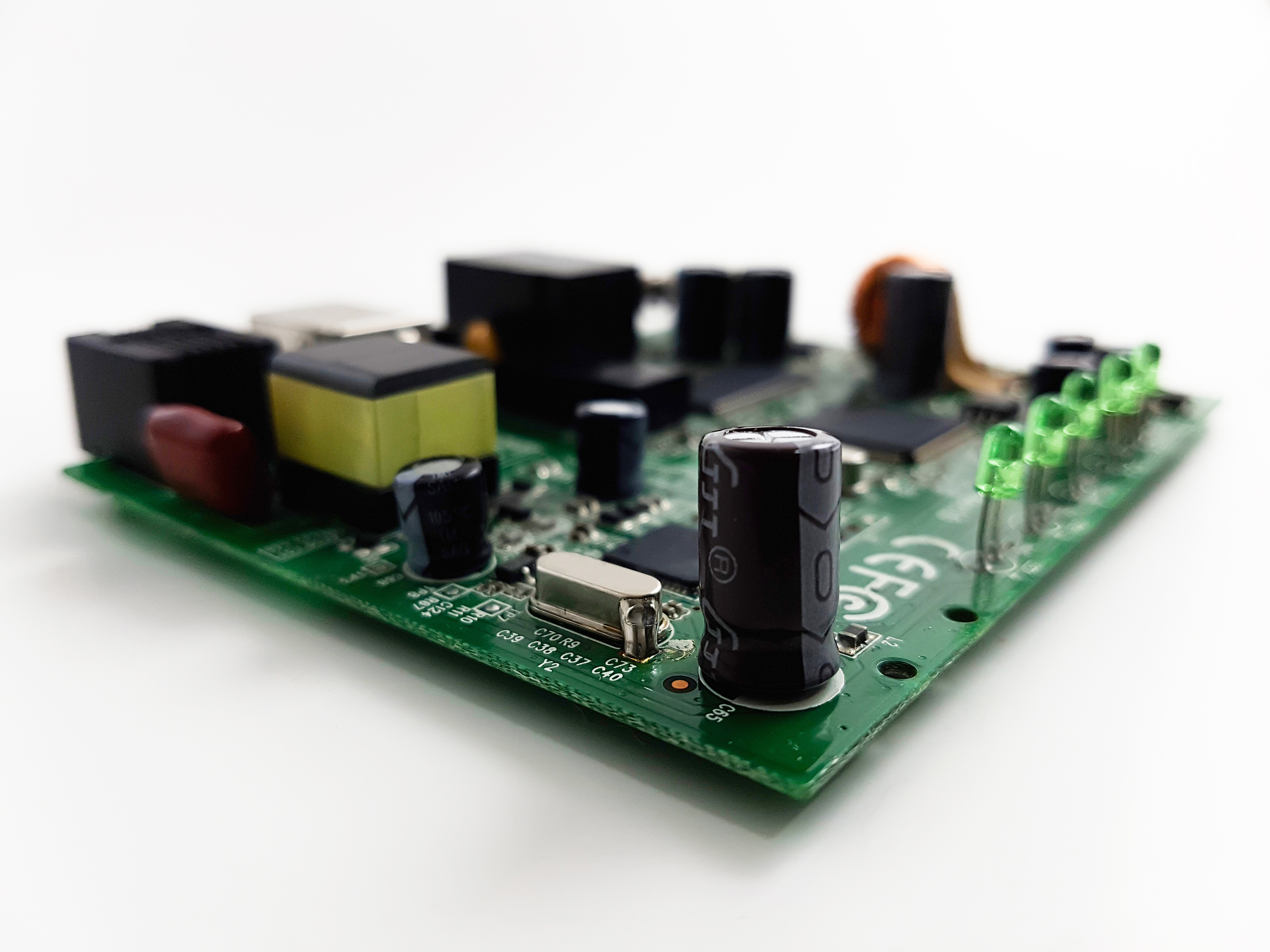

Technical challenges of BMS battery management system and the road to efficient management of lithium-ion batteries

With the popularity of electric vehicles and energy storage systems, lithium-ion batteries have become the mainstream choice due to their high energy density and long cycle life. However, the complexity of lithium-ion batteries also puts higher demands on battery management systems (BMS). This article focuses on the technical challenges of BMS and analyzes its breakthrough directions in the fields of high-precision algorithms, battery consistency management, thermal management optimization, safety and reliability.

1. High-precision algorithm

The SOC (state of charge) and SOH (state of health) estimation of lithium-ion batteries directly affects system performance. Due to the nonlinear characteristics of lithium-ion batteries, traditional algorithms have difficulty coping with multivariate effects such as voltage, temperature, and aging. Currently, AI-driven adaptive algorithms and multi-sensor fusion technology are becoming the focus of optimization to improve the real-time and accuracy of lithium-ion battery management.

2. Battery consistency management

Lithium-ion battery packs are composed of hundreds of cells, and individual differences will lead to uneven capacity decay. BMS needs to dynamically adjust the voltage of each cell through active balancing technology to extend the overall life. For example, the use of capacitor or inductor balancing solutions can reduce the performance loss of lithium-ion battery packs caused by cell differences.

3. Thermal management optimization

Lithium-ion batteries are extremely sensitive to temperature: high temperatures accelerate aging, while low temperatures cause a sudden drop in capacity. BMS needs to integrate efficient heat dissipation design (such as liquid cooling, phase change materials) and intelligent temperature control strategies. For example, in low temperature environments, BMS needs to start the preheating function to ensure that lithium-ion batteries work in the optimal temperature window to avoid performance degradation.

4. Safety and reliability

Thermal runaway of lithium-ion batteries is at the core of safety risks. BMS needs to prevent risks through redundant sensors, fault diagnosis algorithms, and active intervention mechanisms (such as cutting off circuits). For example, multi-layer insulation materials and ceramic coatings are used to suppress heat spread, while redundant MCU designs improve system fault tolerance.

+86 13332949210

+86 13332949210 info@xihobattery.com

info@xihobattery.com

Xiho

Xiho May 09 2025

May 09 2025