Currently, the thermal management of lithium-ion battery systems can be divided into four categories: natural cooling, air cooling, liquid cooling, and direct cooling.

The performance, life and safety of lithium-ion batteries are closely related to temperature management. 15~35℃is the "golden operating range" of lithium-ion batteries - at this temperature, the battery can maximize the energy density advantage while delaying capacity decay. However, how to achieve this goal through thermal management technology? This article focuses on four major solutions: natural cooling, air cooling, liquid cooling, and direct cooling, revealing the underlying logic of thermal management of lithium-ion batteries.

1.Comparison of thermal management solutions: Four ways to cool lithium-ion batteries

(1) Natural cooling: passive energy saving, but only for low-risk scenarios

Natural cooling relies on air convection and does not consume additional energy, but is only applicable to low-power lithium-ion battery systems (such as some LFP lithium iron phosphate battery models). For example, BYD's early Qin and Tang models used natural cooling, but subsequent models equipped with ternary lithium-ion batteries have switched to liquid cooling. Core defect: It is easy to cause the battery pack temperature to get out of control in high temperature environments, threatening the life and safety of lithium-ion batteries.

(2) Air cooling: a balance between low cost and efficiency

Air cooling uses air as the heat exchange medium, which is divided into passive air cooling (directly introducing ambient air) and active air cooling (pre-adjusting air temperature). Early Japanese and Korean electric vehicles mostly adopted this solution, but the air heat exchange efficiency is low, which easily leads to poor battery cell temperature consistency.

(3) Direct cooling: an efficient but niche refrigerant solution

Direct cooling uses the refrigerant phase change to absorb heat, and the heat exchange efficiency is three times that of liquid cooling, but the temperature control accuracy is low, and only a few models such as the BMW i3 have tried it. Limitations: Difficult to adapt to the complex thermal management requirements of high-energy-density lithium-ion batteries.

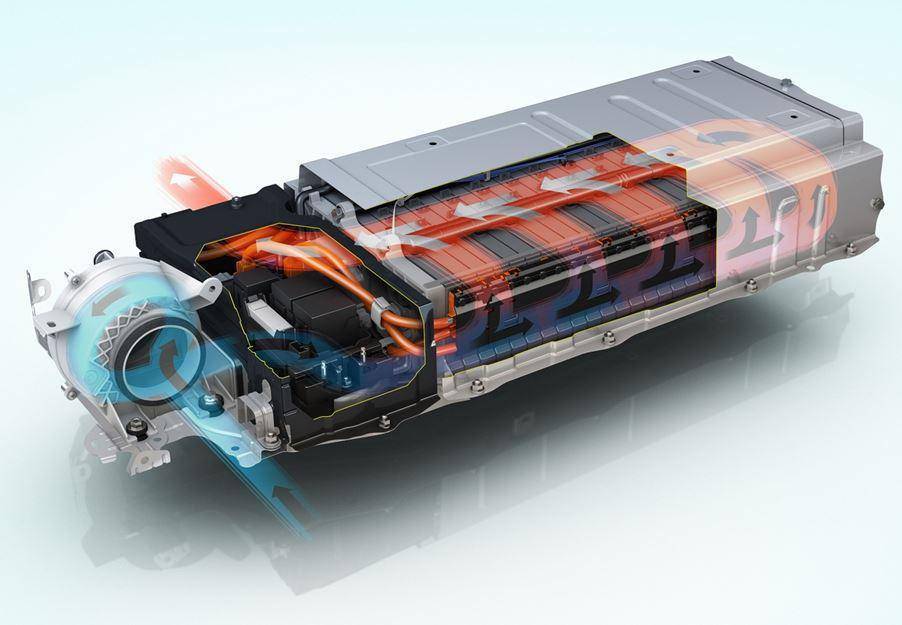

(4) Liquid cooling: The "gold standard" of lithium-ion batteries

Liquid cooling uses ethylene glycol antifreeze as the medium and accurately controls the temperature through a multi-circuit system. For example, Tesla Model S achieves low-temperature heating and high-temperature heat dissipation dual modes by switching the motor cooling circuit and the battery circuit in series/parallel; the general VOLT is designed with independent heat dissipation, air conditioning, and PTC circuits to adapt to complex working conditions.

Advantages of liquid cooling:

Temperature consistency: The temperature difference of hundreds of battery cells is controlled within ±2°C to ensure the accuracy of lithium-ion battery SOC calculation;

High energy density adaptation: Liquid cooling supports the evolution of lithium-ion batteries to high-density technologies such as high-nickel ternary and silicon-based negative electrodes;

Mature supply chain: The migration cost of traditional automotive liquid cooling technology is low, and the reliability of mass production has been verified.

Natural cooling relies on air convection and does not consume additional energy, but is only applicable to low-power lithium-ion battery systems (such as some LFP lithium iron phosphate battery models). For example, BYD's early Qin and Tang models used natural cooling, but subsequent models equipped with ternary lithium-ion batteries have switched to liquid cooling. Core defect: It is easy to cause the battery pack temperature to get out of control in high temperature environments, threatening the life and safety of lithium-ion batteries.

(2) Air cooling: a balance between low cost and efficiency

Air cooling uses air as the heat exchange medium, which is divided into passive air cooling (directly introducing ambient air) and active air cooling (pre-adjusting air temperature). Early Japanese and Korean electric vehicles mostly adopted this solution, but the air heat exchange efficiency is low, which easily leads to poor battery cell temperature consistency.

(3) Direct cooling: an efficient but niche refrigerant solution

Direct cooling uses the refrigerant phase change to absorb heat, and the heat exchange efficiency is three times that of liquid cooling, but the temperature control accuracy is low, and only a few models such as the BMW i3 have tried it. Limitations: Difficult to adapt to the complex thermal management requirements of high-energy-density lithium-ion batteries.

(4) Liquid cooling: The "gold standard" of lithium-ion batteries

Liquid cooling uses ethylene glycol antifreeze as the medium and accurately controls the temperature through a multi-circuit system. For example, Tesla Model S achieves low-temperature heating and high-temperature heat dissipation dual modes by switching the motor cooling circuit and the battery circuit in series/parallel; the general VOLT is designed with independent heat dissipation, air conditioning, and PTC circuits to adapt to complex working conditions.

Advantages of liquid cooling:

Temperature consistency: The temperature difference of hundreds of battery cells is controlled within ±2°C to ensure the accuracy of lithium-ion battery SOC calculation;

High energy density adaptation: Liquid cooling supports the evolution of lithium-ion batteries to high-density technologies such as high-nickel ternary and silicon-based negative electrodes;

Mature supply chain: The migration cost of traditional automotive liquid cooling technology is low, and the reliability of mass production has been verified.

2.Why has liquid cooling become the "standard configuration" for lithium-ion batteries? Three core driving forces.

(1) The rigid demand for high-energy-density lithium-ion batteries

The current energy density of lithium-ion batteries has exceeded 300Wh/kg. Technologies such as high-nickel positive electrodes and silicon-based negative electrodes have increased the risk of thermal runaway. Liquid cooling performs best in thermal runaway protection, sealing, and NVH (noise and vibration).

(2) Cost advantage throughout the life cycle

Although the initial cost of liquid cooling is higher than that of air cooling, it can extend the life of lithium-ion batteries by more than 20% and reduce the overall cost (maintenance + replacement) by 35%.

(3) Cross-industry technology migration

The liquid cooling technology of traditional fuel vehicles (such as engine cooling) has matured, and the lithium-ion battery pack can be directly reused to shorten the development cycle.

From natural cooling to mainstream liquid cooling, the iteration of power battery thermal management technology has always been centered around the performance and safety requirements of lithium-ion batteries. In the future, as new technologies such as solid-state batteries become more popular, liquid cooling systems may be further upgraded, but the core goal remains unchanged: to unleash the potential of each battery cell at the optimal temperature and protect the long life and high safety of lithium-ion batteries.

Welcome to contact us:

WhatsApp/Wechat/Mobile: +86 13332949210

Email: info@xihobattery.com

Website: www.xihopower.com

The current energy density of lithium-ion batteries has exceeded 300Wh/kg. Technologies such as high-nickel positive electrodes and silicon-based negative electrodes have increased the risk of thermal runaway. Liquid cooling performs best in thermal runaway protection, sealing, and NVH (noise and vibration).

(2) Cost advantage throughout the life cycle

Although the initial cost of liquid cooling is higher than that of air cooling, it can extend the life of lithium-ion batteries by more than 20% and reduce the overall cost (maintenance + replacement) by 35%.

(3) Cross-industry technology migration

The liquid cooling technology of traditional fuel vehicles (such as engine cooling) has matured, and the lithium-ion battery pack can be directly reused to shorten the development cycle.

From natural cooling to mainstream liquid cooling, the iteration of power battery thermal management technology has always been centered around the performance and safety requirements of lithium-ion batteries. In the future, as new technologies such as solid-state batteries become more popular, liquid cooling systems may be further upgraded, but the core goal remains unchanged: to unleash the potential of each battery cell at the optimal temperature and protect the long life and high safety of lithium-ion batteries.

Welcome to contact us:

WhatsApp/Wechat/Mobile: +86 13332949210

Email: info@xihobattery.com

Website: www.xihopower.com

+86 13332949210

+86 13332949210 info@xihobattery.com

info@xihobattery.com

Xiho

Xiho Jun 03 2025

Jun 03 2025