The 481kWh specification is a common and standardized capacity unit. It typically refers not to a single large container but to a standard modular cabinet. This capacity is often achieved through the series-parallel configuration of battery cells (e.g., using 314Ah lithium iron phosphate cells). It is a prevalent model for commercial and industrial (C&I) energy storage and small-to-medium-sized projects.

Core Advantage: Why "Liquid Cooling"?

Compared to traditional air-cooled systems, liquid cooling technology offers significant improvements for a 481kWh system:

•Highly Efficient Thermal Management: The specific heat capacity of the liquid coolant (typically a water-glycol solution) is much higher than air, enabling faster and more uniform heat removal. This ensures the battery operates within its optimal temperature range (20-35°C), a key concern for leading lithium ion battery manufacturers.

•Enhanced System Safety: Precise temperature control mitigates thermal runaway risks. The cooling plates physically isolate the coolant from the cells, and the system includes leak detection for added safety.

•Higher Energy Density: Superior cooling efficiency allows for denser cell packing, resulting in more power capacity within a smaller footprint.

•Lower Energy Consumption & Higher Efficiency: The energy required to run coolant pumps is significantly lower than that needed for multiple high-speed fans in air-cooled systems, improving the overall system's energy efficiency.

•Reduced Noise: The elimination of high-speed fans results in quieter operation, making it suitable for noise-sensitive environments like C&I areas.

•Extended Lifespan: Consistent temperature control minimizes cell-to-cell temperature differences (often within 3°C), slowing battery degradation. This focus on longevity is shared by top lithium ion battery manufacturers.

•Enhanced System Safety: Precise temperature control mitigates thermal runaway risks. The cooling plates physically isolate the coolant from the cells, and the system includes leak detection for added safety.

•Higher Energy Density: Superior cooling efficiency allows for denser cell packing, resulting in more power capacity within a smaller footprint.

•Lower Energy Consumption & Higher Efficiency: The energy required to run coolant pumps is significantly lower than that needed for multiple high-speed fans in air-cooled systems, improving the overall system's energy efficiency.

•Reduced Noise: The elimination of high-speed fans results in quieter operation, making it suitable for noise-sensitive environments like C&I areas.

•Extended Lifespan: Consistent temperature control minimizes cell-to-cell temperature differences (often within 3°C), slowing battery degradation. This focus on longevity is shared by top lithium ion battery manufacturers.

Main Application Scenarios

The 481kWh liquid-cooled system is widely applied due to its modularity and efficiency:

•Commercial & Industrial (C&I) Energy Storage: This is the primary application.

1.Peak-Valley Arbitrage: Charging during off-peak hours (low cost) and discharging during peak hours (high cost) to reduce electricity bills.

2.Demand Charge Management: Smoothing power demand to avoid penalties from short-term peak usage.

3.Backup Power: Providing uninterrupted power for critical loads during grid outages.

•Integrated PV, Storage, and Charging Stations: The system stores solar energy from PV carports to power EV chargers, maximizing clean energy use and reducing grid impact.

•Support for Renewable Power Plants: It stabilizes output from distributed solar or small wind farms, increasing renewable energy consumption. The cells sourced from reputable lithium ion battery manufacturers ensure reliability in these applications.

•Grid-Side Ancillary Services: Multiple units can be combined to form larger storage plants for grid services like frequency regulation, where liquid cooling manages heat from rapid charging/discharging.

•Backup Power for Data Centers & Telecom Sites: It serves as a greener, more efficient alternative to traditional UPS and diesel generators, also helping to manage daily energy costs.

1.Peak-Valley Arbitrage: Charging during off-peak hours (low cost) and discharging during peak hours (high cost) to reduce electricity bills.

2.Demand Charge Management: Smoothing power demand to avoid penalties from short-term peak usage.

3.Backup Power: Providing uninterrupted power for critical loads during grid outages.

•Integrated PV, Storage, and Charging Stations: The system stores solar energy from PV carports to power EV chargers, maximizing clean energy use and reducing grid impact.

•Support for Renewable Power Plants: It stabilizes output from distributed solar or small wind farms, increasing renewable energy consumption. The cells sourced from reputable lithium ion battery manufacturers ensure reliability in these applications.

•Grid-Side Ancillary Services: Multiple units can be combined to form larger storage plants for grid services like frequency regulation, where liquid cooling manages heat from rapid charging/discharging.

•Backup Power for Data Centers & Telecom Sites: It serves as a greener, more efficient alternative to traditional UPS and diesel generators, also helping to manage daily energy costs.

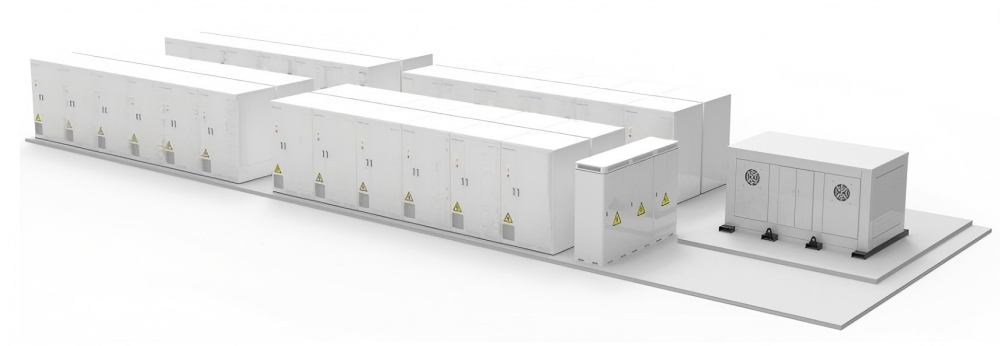

System Configuration (Typical 481kWh Cabinet)

A complete system includes:

•Battery System: The core, comprising battery cells organized into modules and packs. Partnering with reliable lithium ion battery manufacturers is crucial for quality.

•Liquid Cooling System: Includes cooling plates, pumps, piping, and heat exchangers.

•Power Conversion System (PCS): Converts DC power from the batteries to AC power for the grid or load.

•Energy Management System (EMS): The "brain" that controls charging/discharging strategies and monitors performance.

•Fire Protection System: Typically uses gas or water mist suppression agents.

•Enclosure: Often a standardized cabinet for easy deployment.

•Liquid Cooling System: Includes cooling plates, pumps, piping, and heat exchangers.

•Power Conversion System (PCS): Converts DC power from the batteries to AC power for the grid or load.

•Energy Management System (EMS): The "brain" that controls charging/discharging strategies and monitors performance.

•Fire Protection System: Typically uses gas or water mist suppression agents.

•Enclosure: Often a standardized cabinet for easy deployment.

Future Trends

•Standardization: The 481kWh cabinet is becoming a standard "building block" for C&I storage, enabling rapid, scalable deployment.

•AI & Intelligence: EMS will use AI algorithms to optimize dispatch based on weather, load forecasts, and electricity prices, maximizing ROI. This aligns with innovations from progressive lithium ion battery manufacturers.

•Full Lifecycle Management: Digital platforms will monitor battery health in real-time, supporting future secondary use (e.g., backup power).

•Virtual Power Plant (VPP) Participation: Numerous distributed 481kWh systems can be aggregated into a VPP to participate in energy markets. The quality of components from leading lithium ion battery manufacturers is vital for this.

•AI & Intelligence: EMS will use AI algorithms to optimize dispatch based on weather, load forecasts, and electricity prices, maximizing ROI. This aligns with innovations from progressive lithium ion battery manufacturers.

•Full Lifecycle Management: Digital platforms will monitor battery health in real-time, supporting future secondary use (e.g., backup power).

•Virtual Power Plant (VPP) Participation: Numerous distributed 481kWh systems can be aggregated into a VPP to participate in energy markets. The quality of components from leading lithium ion battery manufacturers is vital for this.

The 481kWh liquid-cooled energy storage system strikes an optimal balance between technology, cost, and market needs. Leveraging the safety and efficiency of liquid cooling, it is widely used in C&I peak-shaving, PV-storage-charging integration, and renewable energy support. It is a cornerstone of the energy transition. The industry relies on partnerships with leading lithium ion battery manufacturers to ensure the performance of these standardized units, which are also championed by major lithium ion battery manufacturers for their scalability. Furthermore, the design standards are influenced by the best practices of global lithium ion battery manufacturers, and the supply chain depends on innovative lithium ion battery manufacturers.

Contact our team today for a complimentary, customized consultation!

Inquiry more product details from the : Lithium Ion Battery Manufacturers

WhatsApp/Wechat/Mobile: +86 13332949210

Email: info@xihobattery.com

Website: www.xihopower.com

WhatsApp/Wechat/Mobile: +86 13332949210

Email: info@xihobattery.com

Website: www.xihopower.com

+86 13332949210

+86 13332949210 info@xihobattery.com

info@xihobattery.com

Xiho

Xiho Oct 29 2025

Oct 29 2025