Differences in cell sorting control parameters

During the production process of battery cells, even for batteries of the same manufacturer and model, there will be slight differences in key parameters between different batches. For example, the capacity, internal resistance, self-discharge rate, etc. of the battery cells. In terms of battery cell capacity, different batches of battery cells may have different actual storable charges due to factors such as raw material characteristics and production environment.

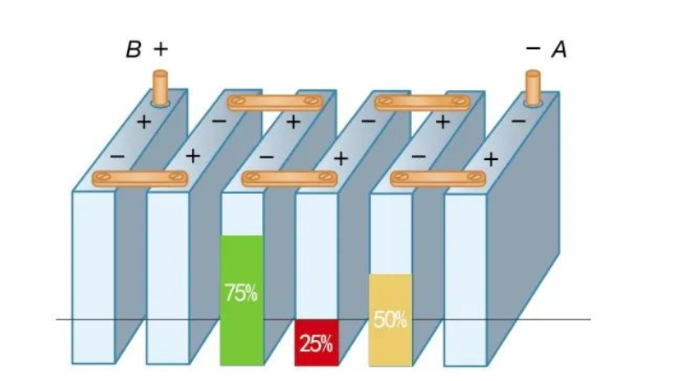

When different batches of battery cells are mixed, the battery cells with small capacity will be fully charged and discharged first, limiting the available capacity of the entire energy storage system. Different internal resistances will cause the battery cells to heat up differently during the charging and discharging process. The battery cells with large internal resistance will heat up more seriously, affecting the stability and safety of the system. Inconsistent self-discharge rates will cause different battery cells to consume different amounts of power when the system is stationary. Over time, the initial charge state of each battery cell will vary greatly, affecting the overall performance of the system.

Impact of battery cell technology

There may be improvements or fine-tuning in the production process of different batches of battery cells. For example, the coating thickness of the electrode material, slight changes in the electrolyte formula, etc. These seemingly minor process changes will have a direct impact on the performance of the battery cell. Inconsistent coating thickness will change the energy density and charge and discharge performance of the battery cell; differences in electrolyte formulas may affect the cycle life and high and low temperature performance of the battery cell. If battery cells with different processes are mixed for energy storage systems, due to their asynchronous performance characteristics, they cannot work in coordination during the charge and discharge process, and it is easy for some battery cells to be over-charged and discharged, while some battery cells are under-charged and discharged, accelerating the aging and damage of the battery cells.

Impact on system life

The life of the energy storage system depends largely on the life of the battery cells. Due to the differences in the above parameters and processes, the cycle life of different batches of battery cells is also different. After a certain number of charge and discharge cycles, the performance of the battery cells with a short cycle life will drop sharply, or even fail. While other battery cells may still be in normal working condition, this will cause the entire energy storage system to be unable to operate normally due to the damage of some battery cells, greatly shortening the overall service life of the system. At the same time, the speed of performance degradation of different batches of battery cells is inconsistent, which will make the performance of the system gradually unstable, increasing maintenance costs and operating risks.

Impact on system efficiency

From the perspective of system efficiency, mixing different batches of battery cells will lead to lower energy conversion efficiency. Due to the different charging and discharging characteristics of each battery cell, complex balancing control of the entire system is required during the charging and discharging process to ensure that each battery cell can work normally. But even so, it is difficult to completely eliminate the differences between battery cells, resulting in additional energy loss during the balancing process. In addition, different batches of battery cells have different response speeds. When faced with rapidly changing power demands, they cannot respond synchronously, resulting in unstable power output of the system, affecting the efficiency and reliability of the energy storage system in practical applications.

In summary, in order to ensure the performance, life, efficiency and safety of the energy storage system, the use of cells from different batches should be avoided.

Find a reliable supplier of battery cells seller or battery packs manufacturer who made energy storage battery pack with A grade cells,pls contact XIHO!

WhatsApp/Wechat/Mobile: +86 13332949210

Email: info@xihobattery.com

Website: www.xihopower.com

+86 13332949210

+86 13332949210 info@xihobattery.com

info@xihobattery.com

Xiho

Xiho Mar 18 2025

Mar 18 2025